food For US Maple Syrup Producers, Climate Change and Competition Threaten a Way of Life

As sap season grows shorter and warmer, New England’s sugarmakers are grappling with the implications for the region’s industry and identity.

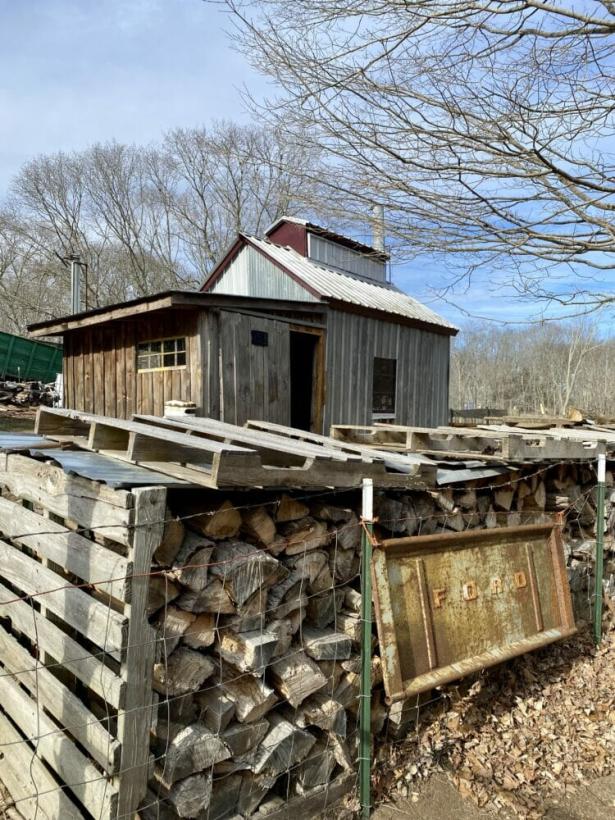

“Sap season is over,” John Hall declared on March 4, 2023. At Maple Breeze Farm in Westbrook, Connecticut, the fleeting period in which weather conditions allow a maple tree to be tapped for sap had ended twenty-three days earlier than the previous year and ran about two weeks shorter.

For most of the world, sap season comes and goes as invisibly as the sap that flows beneath a tree’s bark. For Hall, whose family has been producing syrup from the woods on this plot of land since 1635, his wife Bonnie and other farmers in the Northeastern United States and Eastern Canada, this transition between winter and spring is a season in its own right.

Very little about the process of sugaring (harvesting sap from maple trees) on Maple Breeze Farm has changed in the last four centuries, but this season the Halls are facing unprecedented challenges as a result of global changes in weather patterns and the marketplace.

“Sugaring is very weather dependent,” explains Hall. “And this year, we didn’t have any winter.”

Just a few degrees makes all the difference—too many warm days in February and there will be less maple syrup for all the months to follow.

The winter season spanning 2022-2023 was the warmest on record for Connecticut, according to the National Oceanic and Atmospheric Administration. Using information provided by the Northeast Regional Climate Center, the NOAA reported the average regional temperature for the season as 31.9 degrees Fahrenheit, 5.2 degrees warmer than normal.

For the Halls, the consequences of this warm winter are immediately evident in the minimal yield from this sap season: less than forty gallons of maple syrup, about half of last year’s seventy-four gallons.

As the climate changes, pushing ideal sugaring conditions to the north and threatening maple syrup production in the region, having diversified sources of income bolsters the long-term financial sustainability of farms such as Maple Breeze.

A recent Frontiers survey of more than 100 American maple syrup producers (more than half based in New England) reported that only 12% declared maple sales as their primary source of income; for nearly half of participants, maple sales account for no more than 5% of annual income. The Halls’ primary revenue, for example, comes from other agricultural ventures, including sales of pork, beef, lamb and eggs from animals raised on their farm.

At the scale of a single farm, the impact of slightly warmer weather may seem small, but for the U.S., which valued the production of maple syrup in 2021 at $134 million, the movement of a great portion of this industry across the Canadian border would be a substantial economic loss.

Whether or not the livelihood of farmers like John and Bonnie depends on maple syrup, sugaring is an integral part of New England culture and plays a role in the local economy not only as an agricultural good but as a driver of regional tourism. Of those surveyed by Frontiers, 86% said that maple products are an important component of local tourism.

The Maple Syrup Producers of Connecticut Association hosts Maple Weekend each year. On these two days, residents and travelers alike are invited to visit sugar shacks throughout the state to see how maple syrup is made and to buy maple products. This year’s Maple Weekend was scheduled for March 18 and 19th—two full weeks after sap season had finished for most producers. As weather patterns change, it may become harder to connect agricultural events with tourist attractions, impacting the economic stability of both sectors.

During sap season, when there is a briefly perfect balance of freezing nights and cool days, the Halls have about a thousand taps (spouts that act as a funnel from which the sap flows) in maple trees ranging from twenty-five to four hundred years old. To avoid overstressing their trees, the Halls tap just once each season and work according to natural cycles. Part of this means continuing traditional sugaring practices that originated with the Indigenous populations of North America, rather than transitioning to the use of modern tools that would expedite the process.

“We’re not into the latest technology,” says Hall, who points to images in a farmers catalog of machines that quickly vacuum sap from trees. “All of our sap runs out of the tree with gravity.”

About fifty gallons of sap are needed to make just one gallon of pure maple syrup. Although some producers have switched to gasoline-fueled machinery, the Halls boil their sap over fire as their family has done for generations, using wood from trees that have fallen on their farm. As the sap boils, the liquid condenses and takes on a darker hue.

The syrup is labeled for sale in accordance with a standardized grading system based on color, ranging from Golden to Amber to Dark to Very Dark. Every bottle of Maple Breeze Farm syrup is graded Dark. “The darker you go, the stronger the maple flavor is,” says Hall. A spoonful of the Halls’ syrup is a testament to this fact—it is as rich in flavor as it is in color, not only sweet but slightly earthy, redolent of the soil and bark from which it came.

Maple Breeze Farm products are available for purchase only at nearby farmers markets or from their farmstand, as is often the case with artisanal maple producers, who do not generate the quantity necessary to stock supermarket shelves. Additionally, face-to-face interactions offer a chance to explain not only what makes their syrup special but also why it may seem expensive compared to others.

At more than a dollar an ounce, Maple Breeze Farm syrup still does not fully reflect the amount of labor distilled into each bottle and the cost of materials, which has skyrocketed since the start of the pandemic and the subsequent supply chain crisis. “We’re not in it for the money,” says Bonnie Hall. “I don’t think we sell anything for a profit.”

Commercial producers in places such as Vermont and Quebec are able to drive down the price of syrup while increasing their profit margin by packaging it for wholesale and sourcing from many different farms.

When it comes to branding maple syrup from numerous farms under one label, Bonnie comments, “It’s not illegal, but to us it’s immoral. Our syrup has our name on it. It’s our trees. It’s our story.”

In some ways, it is this close connection with maple trees and the sugaring tradition that is most at risk for New Englanders. For the trees and the traditions to be preserved for generations to come, action must be taken at the individual and industry levels with consideration for environmental, economic and social sustainability.

Farmers like John and Bonnie are doing their best on the frontlines of climate change to care for their land, while also participating in politics to influence decisions that affect local ecosystems. As the situation grows more dire, institutions in the area are starting to lend their support by investing resources into innovative opportunities. The Forest School at the Yale School of the Environment launched the Maple Education and Extension Program last year with the specific intention to help New England’s maple syrup makers develop more sustainable production methods and adapt to the effects of climate change.

For the Halls and other farmers in the Northeast, the future will depend, as always, on continuing a careful conversation with their trees and their community.

Spread the word