Why is the United States running out of face masks for medical workers? How does the world’s wealthiest country find itself in such a tragic and avoidable mess? And how long will it take to get enough protective gear, if that’s even possible now?

I’ve spent the last few days digging into these questions, because the shortages of protective gear, particularly face masks, has struck me as one of the more disturbing absurdities in America’s response to this pandemic.

Yes, it would have been nice to have had early, widespread testing for the coronavirus, the strategy South Korea used to contain its outbreak. It would be amazing if we can avoid running out of ventilators and hospital space, the catastrophe that has befallen parts of Italy. But neither matters much — in fact, no significant intervention is possible — if health care workers cannot even come into contact with coronavirus patients without getting sick themselves.

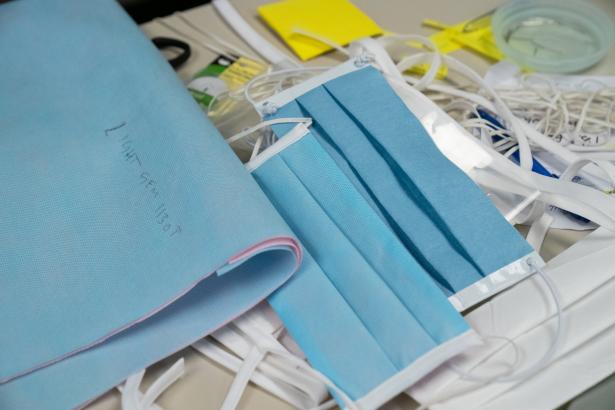

That’s where cheap, disposable face masks, eye protection, gloves and gowns come in. That we failed to procure enough safety gear for medical workers — not to mention for sick people and for the public, as some health experts might have recommended if masks were not in such low supply — seems astoundingly negligent.

What a small, shameful way for a strong nation to falter: For want of a 75-cent face mask, the kingdom was lost.

I am sorry to say that digging into the mask shortage does little to assuage one’s sense of outrage. The answer to why we’re running out of protective gear involves a very American set of capitalist pathologies — the rise and inevitable lure of low-cost overseas manufacturing, and a strategic failure, at the national level and in the health care industry, to consider seriously the cascading vulnerabilities that flowed from the incentives to reduce costs.

Perhaps the only way to address the shortfall now is to recognize that the market is broken, and to have the government step in to immediately spur global and domestic production. President Trump, bizarrely, has so far resisted ordering companies to produce more supplies and equipment. In the case of masks, manufacturers say they are moving mountains to ramp up production, and some large companies are donating millions of masks from their own reserves.

But given the vast global need for masks — in the United States alone, fighting the coronavirus will consume 3.5 billion face masks, according to an estimate by the Department of Health and Human Services — corporate generosity will fall short. People in the mask business say it will take a few months, at a minimum, to significantly expand production.

“We are at full capacity today, and increased production by building another factory or extending further will take anywhere between three to four months,” said Guillaume Laverdure, the chief operating officer of Medicom, a Canadian company that makes masks and other protective equipment in factories around the world.

And though some nontraditional manufacturers like T-shirt factories and other apparel makers have announced plans to rush-produce masks, it’s unclear that they will be able to meet required safety standards or shift over production in time to answer demand.

Few in the protective equipment industry are surprised by the shortages, because they’ve been predicted for years. In 2005, the George W. Bush administration called for the coordination of domestic production and stockpiling of protective gear in preparation for pandemic influenza. In 2006, Congress approved funds to add protective gear to a national strategic stockpile — among other things, the stockpile collected 52 million surgical face masks and 104 million N95 respirator masks.

But about 100 million masks in the stockpile were deployed in 2009 in the fight against the H1N1 flu pandemic, and the government never bothered to replace them. This month, Alex Azar, secretary of health and human services, testified that there are only about 40 million masks in the stockpile — around 1 percent of the projected national need.

As the coronavirus began to spread in China early this year, a global shortage of protective equipment began to look inevitable. But by then it was too late for the American government to do much about the problem. Two decades ago, most hospital protective gear was made domestically. But like much of the rest of the apparel and consumer products business, face mask manufacturing has since shifted nearly entirely overseas. “China is a producer of 80 percent of masks worldwide,” Laverdure said.

Hospitals began to run out of masks for the same reason that supermarkets ran out of toilet paper — because their “just-in-time” supply chains, which call for holding as little inventory as possible to meet demand, are built to optimize efficiency, not resiliency.

“You’re talking about a commodity item,” said Michael J. Alkire, president of Premier, a company that purchases medical supplies for hospitals and health systems. In the supply chain, he said, “by definition, there’s not going to be a lot of redundancy, because everyone wants the low cost.”

In January, the brittle supply chain began to crack under pressure. To deal with its own outbreak, China began to restrict exports of protective equipment. Then other countries did as well — Taiwan, Germany, France and India took steps to stop exports of medical equipment. That left American hospitals to seek more and more masks from fewer and fewer producers.

People in the industry assured me they would prepare better next time. “We are laserlike focused to ensure that our health care systems are never in this scenario again,” Alkire told me. “There will be a lot more domestic manufacturing of these products going forward.”

I don’t doubt it — but that we did not plan, as a nation, for this entirely predictable shortage makes me wonder what other inevitable pothole is lurking out there for all to trip over. Getting enough protective gear was among the cheapest, most effective things we could have done to slow down the pandemic. That we failed on such an obvious thing reveals an alarming national incapacity to imagine and prepare for the worst.

We will get enough masks in time for the next disaster. But wouldn’t it be nice, for once, if we prepared for trouble before it hit us in the face?

Farhad Manjoo became a Times Opinion columnist in 2018.

Before that, they wrote The Times’ State of the Art column, covering the technology industry’s efforts to swallow up the world. They have also written for Slate, Salon, Fast Company and The Wall Street Journal. To their chagrin, their 2008 book, “True Enough: Learning to Live in a Post-Fact World,” accurately predicted our modern age of tech-abetted echo chambers and “alternative facts.”

Farhad Manjoo was born in South Africa and emigrated with their family to Southern California in the late 1980s. They live in Northern California with their wife and two children.

Spread the word